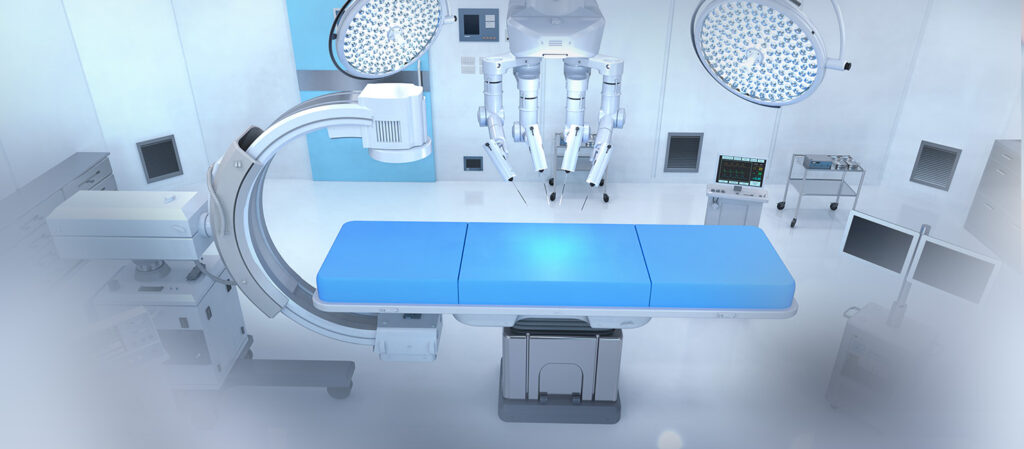

Validation – Clean Rooms, Operating Rooms & BMTU

Creating Controlled Environments with Confidence

In pharmaceuticals, biotechnology, and advanced healthcare, the integrity of your controlled environment is non-negotiable. Even a minor deviation can compromise product sterility, research validity, and personnel safety. MES provides comprehensive validation and performance testing for clean rooms, biosafety cabinets, and laminar airflow systems. We ensure your critical environments consistently meet the stringent requirements of ISO 14644, WHO GMP, and other global standards, giving you the confidence to operate without compromise.

Our Validation Services: A Foundation of Quality

We offer a complete suite of tests to certify every aspect of your controlled environment.

-

Clean Room Certification: Performance verification and issuance of as-built, at-rest, and operational certificates in compliance with ISO 14644-1 standards.

-

Biosafety Cabinet (BSC) Testing: Annual certification, Airflow velocity testing, and HEPA filter integrity testing (DOP/PAO challenge) as per NSF/ANSI 49 and ISO 14644.

-

Laminar Air Flow (LAF) Workstation Validation: Ensuring Class A/ISO 5 conditions are maintained for critical processes.

-

Monitoring Parameters: Air Velocity, Filter Integrity, Particle Count, Differential Pressure, Flow pattern test, Recovery Test, Environmental Mornitoring such as temperature/humidity mapping.

Our process is rigorous, documented, and designed to leave no room for error.

Risk-Based Approach: We focus on your most critical parameters and areas to ensure the highest level of control where it matters most.

Certified Equipment & Traceable Standards: We use advanced, calibrated particle counters, anemometers, and photometers with certificates traceable to NPL.

Detailed Reporting & Documentation: You receive a comprehensive validation report with raw data, summary analysis, and clear pass/fail status, essential for regulatory audits.

Non-Compliance Resolution: We don’t just identify issues; we provide expert guidance and support to rectify them and achieve compliance.

Beyond a compliance checkbox, validation is a core component of your quality system.

Patient Safety: Our validation processes ensure controlled, contamination-free environments that protect patient safety at every stage of care.

Ensure Product Sterility & Safety: Protect pharmaceuticals, implants, and medical devices from particulate and microbial contamination.

Safeguard Personnel & Environment: Verify that Biosafety Cabinets provide effective containment for hazardous biological agents.

Maintain Regulatory Compliance: Meet the mandatory requirements for audits from WHO-GMP, US FDA, and other national and international bodies.

Protect Research Integrity: Guarantee that sensitive experiments and processes are not compromised by environmental variables.

Prevent Costly Failures: Proactive identification of filter failures or room integrity issues prevents batch losses and operational shutdowns.

Our expertise is critical for industries where environmental control is paramount.

Pharmaceutical & Biotechnology Manufacturing

Medical Device & Implant Production

Hospital Sterile Services Departments (SSD) & OT Suites

Vaccine Research & Development Laboratories

Food & Dairy Industries

Academic & Government Research Institutes

Validate your Environment with the Experts.